In industries ranging from manufacturing to mining, conveyor systems are the lifeblood of operations, ensuring the efficient movement of materials and products. However, these systems are not without risks. One critical component that often goes overlooked is the inspection door on conveyor chutes. These doors serve as access points for maintenance, troubleshooting, and inspections – but when not designed or maintained properly, they can become a significant safety hazard. In this post, we’ll explore the benefits of safe inspection door design and the industry regulations that govern their use, helping you protect your workforce and avoid costly compliance violations.

Why Inspection Doors Matter

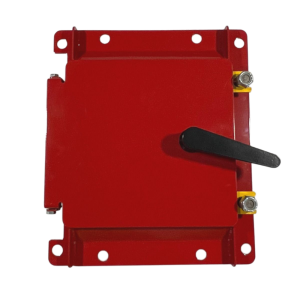

Conveyor chutes are often located in high-traffic or hard-to-reach areas, making them prone to blockages, wear, and mechanical failures. Inspection doors provide essential access for workers to perform maintenance, clear obstructions, or inspect for damage. However, these doors must be engineered with safety in mind. A poorly designed or improperly maintained inspection door can lead to:

- Falls or entrapment due to missing guards or hinges.

- Unauthorized access by workers unfamiliar with the risks.

- Equipment malfunctions caused by undetected issues.

By prioritizing inspection door safety, companies can mitigate these risks and ensure smooth operations.

Benefits of Safe Inspection Door Design

- Enhanced Safety for Workers: A well-designed and properly installed inspection door prevents unauthorized access to the chute, reducing the risk of accidents, injuries, or fatalities.

- Easier Maintenance Access: Inspection doors with ergonomic handles, clear signage, and accessible locations make maintenance tasks faster and safer. This reduces the time workers spend navigating around conveyor systems and minimizes exposure to hazards.

- Compliance with Industry Regulations: Adhering to safety standards isn’t just a legal requirement – it’s a proactive measure that protects your business from fines, lawsuits, and reputational damage. Properly designed inspection doors help companies meet OSHA/MSHA, ANSI/ASME, ISO, and industry-specific regulations, ensuring compliance during inspections.

- Reduced Downtime and Costs: When inspection doors are safe and easy to access, maintenance teams can quickly address issues before they escalate into major breakdowns. This reduces unplanned downtime and the likelihood of costly repairs, replacements, lost productivity, or even product recalls.

- Long-Term Cost Savings: Investing in high-quality inspection doors with safety features may have a higher upfront cost, but it pays off in the long run by preventing accidents, reducing insurance premiums, and extending the lifespan of conveyor systems.

Industry Regulations

Several industries have established guidelines for conveyor chute inspection door safety to ensure compliance with regulatory requirements. Some notable regulations include:

- OSHA / MSHA Guidelines: The Occupational Safety and Health Administration (OSHA) and Mine Safety and Health Administration (MSHA) provide guidelines on machinery and equipment in general industry standards.

- ASME B20.1 / ANSI B11.19: The American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) established standards for Conveyors Safety Set, including inspection doors. ISO 1819 sets international safety standards for Continuous Mechanical Handling Equipment.

- NFPA Guidelines: The National Fire Protection Association (NFPA) provides guidelines on conveyor systems in the context of fire protection.

- Industry-Specific Regulations: Various industries have their own regulations and standards, such as food processing (e.g., HACCP), pharmaceuticals (e.g., FDA regulations), and manufacturing.

Best Practices for Inspection Door Safety

To ensure compliance and maximize safety, follow these best practices:

- Proper Installation: Ensure the inspection door is installed according to manufacturer instructions and industry guidelines.

- Regular Inspections: Conduct regular inspections of the conveyor system, including the inspection door, to identify potential issues early on. Check for wear, corrosion, or damage to doors, hinges, and locking mechanisms.

- Training: Train personnel on proper use, maintenance, and operation of the inspection door and surrounding conveyor system.

- Use Clear Signage: Label doors with warnings like “Keep Door Closed During Operation” and “Authorized Personnel Only.”

- Lockout/Tagout Procedures: Implement lockout/tagout (LOTO) protocols for scheduled maintenance or repairs to prevent accidental start-up during maintenance.

- Choose High-Quality Doors: Invest in doors with safety-certified materials and ergonomic design.

Conclusion

Conveyor chute inspection door safety is a critical component of any industrial operation. By prioritizing ergonomic design, compliance with regulations, and regular maintenance, companies can protect their workers, avoid costly fines, and ensure uninterrupted productivity. Whether you’re in manufacturing, mining, or food processing, adhering to standards like OSHA, ISO, and industry-specific guidelines is essential.

Remember: A safe inspection door isn’t just a regulatory checkbox – it’s a commitment to the well-being of your workforce and the longevity of your operations. Take the time to review your current systems, consult safety experts, and invest in solutions that align with both safety and efficiency.

Additional Resources

- OSHA / MSHA Guidelines

- ASME B20.1 / ANSI B11.19 – Conveyors Safety Set

- ISO 1819 Safety Code

- NFPA Guidelines

By implementing these guidelines and best practices, companies can ensure the safe operation of their conveyor systems, protecting workers and minimizing the risk of accidents and injuries.

What steps is your organization taking to ensure inspection door safety? Share your insights in the comments below!

Leave a Reply