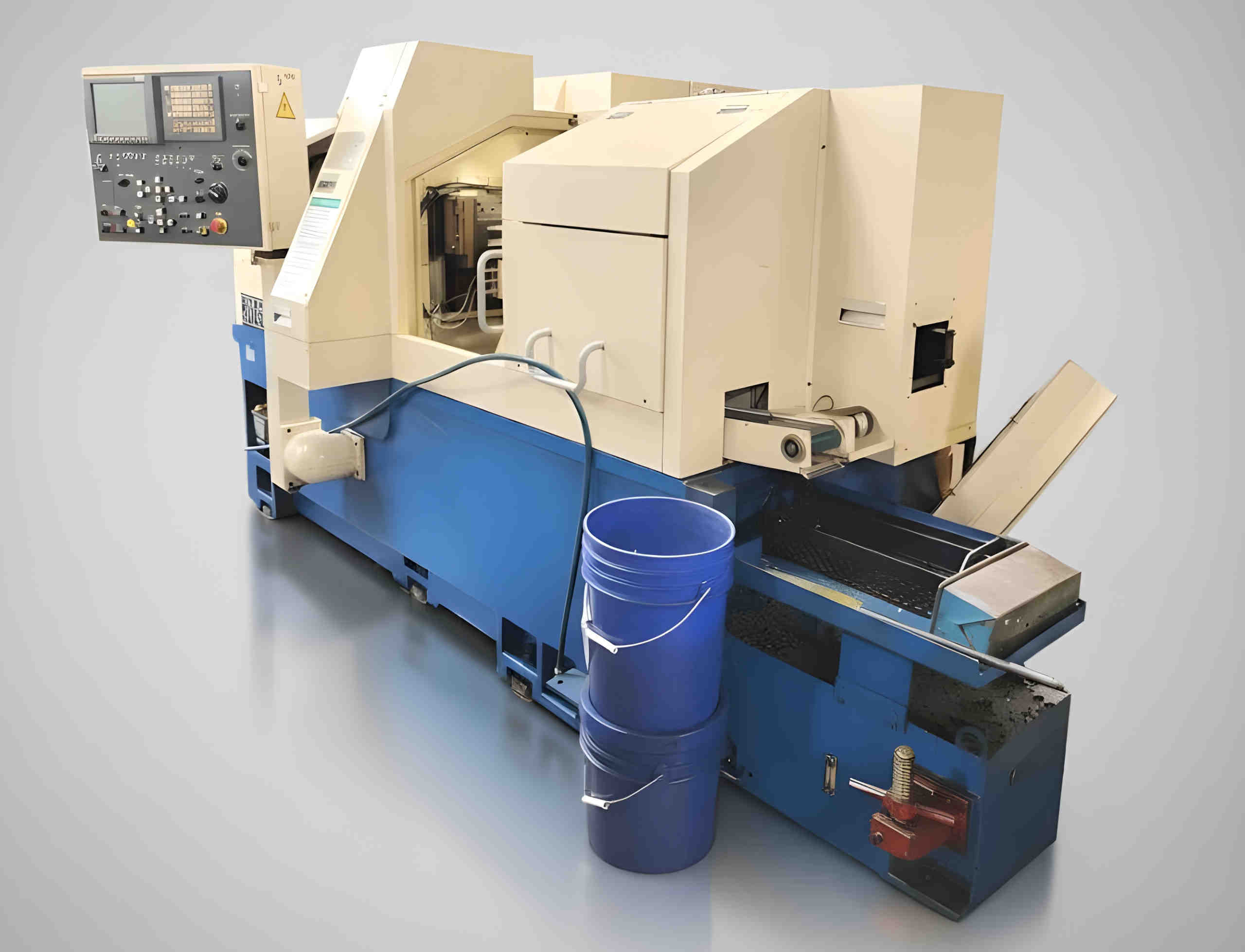

When it comes to manufacturing intricate, high-precision parts, the Tsugami BU-26SY 9-axis CNC gang/turret Swiss lathe stands out as a powerhouse of innovation. Released in 2005, this machine redefined what’s possible in small-part machining, combining advanced technology with user-friendly design. Whether you’re in aerospace, medical device manufacturing, or automotive engineering, the BU-26SY is a staple for creating complex components with unmatched accuracy. Let’s break down its capabilities, ease of use, and why it’s still a favorite in modern workshops.

What Makes the BU-26SY Unique?

The 9-axis configuration is the star of the show. Unlike traditional lathes, which often require multiple setups, the BU-26SY can perform simultaneous operations – like turning, milling, drilling, and threading – on a single workpiece. This reduces production time and minimizes errors. Key features include:

- Gang Tooling and Turret System: The machine’s gang tooling allows multiple tools to be mounted on a single turret, enabling quick tool changes and efficient machining.

- High Precision: Capable of producing parts with micron-level accuracy, ideal for industries where tolerances are critical (e.g., medical implants or aerospace components).

- Material Versatility: Handles a wide range of materials, including stainless steel, titanium, aluminum, and exotic alloys.

- Speed and Efficiency: With spindle speeds up to 10,000 RPM and rapid traverse rates, it’s built for high-volume production without compromising quality.

Ease of Use: Designed for Operators, Not Just Engineers

The BU-26SY isn’t just powerful – it’s also intuitive. Its user-friendly interface and advanced CNC programming make it accessible to operators with varying levels of expertise. Key advantages include:

- Touchscreen Controls: Modern upgrades (even on older models) often include graphical displays for real-time monitoring of tool paths and machine status.

- Integration with CAD/CAM Software: Seamless compatibility with programs like Mastercam or SolidWorks allows for quick setup and reduced programming time.

- Safety Features: Built-in collision detection and emergency stop systems ensure safe operation, even during complex multi-axis tasks.

Common Use Cases: Where Does It Shine?

The BU-26SY is a go-to machine for industries that demand small, complex parts with tight tolerances. Some of its most common applications include:

- Medical Device Manufacturing: Producing surgical instruments, orthopedic implants, and pacemaker components with extreme precision.

- Aerospace Components: Machining turbine blades, fuel nozzles, and landing gear parts that require high strength and reliability.

- Automotive Industry: Creating precision gears, sensor housings, and fuel injection components for high-performance vehicles.

- Electronics: Manufacturing micro connectors, semiconductor parts, and miniaturized components for advanced devices.

Why Accessories Matter: Enhancing Performance

While the BU-26SY is a robust machine on its own, the right accessories can unlock its full potential. Key accessories include:

- Coolant Systems: Essential for chip evacuation and tool longevity, especially when machining tough materials like titanium.

- Workholding Devices: Custom chuck systems and collets ensure secure clamping of small, delicate parts.

- Tooling Kits: High-quality end mills, drills, and taps tailored for the BU-26SY’s turret system improve efficiency and reduce downtime.

- Automation Options: Adding bar feeders or robotic arms enables unattended operation, boosting productivity in high-volume environments.

Statistics and Industry Impact

Though specific production data for the BU-26SY isn’t publicly available, industry reports highlight its longevity and reliability. Many manufacturers report:

- 30% faster production times compared to older 5-axis machines, thanks to the 9-axis capability.

- Reduced scrap rates by up to 25% due to the machine’s precision and multi-tasking features.

- Lower maintenance costs over time, as the BU-26SY’s design minimizes wear and tear on tools and components.

Why It Still Matters in 2025

Even two decades after its release, the BU-26SY remains a cornerstone of precision machining. Its ability to handle complex geometries, small batch runs, and high-accuracy demands makes it indispensable for industries that rely on quality over quantity. For shops looking to upgrade or expand their capabilities, the BU-26SY offers a proven, reliable solution that bridges the gap between traditional machining and modern automation.

Additional Resources

- Tsugami America: https://tsugamiamerica.com

- Tsugami is an ISO 9001:2015 Certified Quality Management System (QMS)

- ANSI B11.6-2022 outlines the safety requirements for manual turning machines (lathes) and can also apply to those with automatic control

Final Thoughts

The Tsugami BU-26SY 9-axis CNC gang/turret Swiss lathe isn’t just a machine – it’s a symbol of precision engineering. Whether you’re a seasoned machinist or new to the field, its combination of power, versatility, and ease of use makes it a must-have for any workshop aiming to deliver top-tier components in today’s competitive market.

If you’re considering upgrading your equipment or exploring new manufacturing possibilities, the BU-26SY is a name worth noting. After all, in the world of precision machining, the right tool can make all the difference.

Leave a Reply